Oil and Gas CNC Machining

Machinery and equipment used in oil and gas exploration and production, including drilling machinery requires high-performance components that will reliably operate in harsh environments. We have worked with oil and gas industry leaders for over a decade, establishing long-term partnerships with Miller CNC. Our exotic alloy expertise along with advanced technological CNC machining processes has made us a valued manufacturer of high-performance oil and gas components.

Precision Components for the Oil and Gas Industry

We understand the oil and gas industry requires an agile CNC machine shop to respond efficiently to changing industry conditions. We remain a globally competitive CNC machine manufacturer for oil and gas leaders due to our robust supply chain and on-time delivery of performance-built components.

Oil and Gas Superalloy Material Expertise

Miller CNC specializes in working with hard-to-machine metals, including:

Stainless Steels

- Custom 455

- 300/400 Series

- 13-8MO

- 15-5PH

- 17-4PH

- Nitronic 40/50/60

Superalloys

- A-286

- Invar

- Kovar

- Inconel 625

- Inconel 718

- Monel

- Titanium

- Haynes

Robust Supply Chain for On-Time Delivery

Our supply chain includes Mil-Spec, AN-spec, and AMS-spec certified sub-vendors. We also work with customer-approved sources that allow us to manufacture your components on-time, with every project.

CNC Machining Equipment and Software for High-Quality Parts

Our CNC machining equipment includes 3-axis milling and 5-axis milling machining centers. We also have CNC lathes for CNC turning options for high-quality machined parts.

Software we utilize includes:

- Full 5-axis HyperMill CAM system with machine simulation

- MasterCAM x2 software

- PC-DMIS CAD+ software

- Shoptech E2 management software

- Solidworks software

Discuss Your Oil and Gas Project with Us

Find out how Miller CNC can help you for your next oil and gas CNC machining project. Call us at 619-501-9866 or contact us.

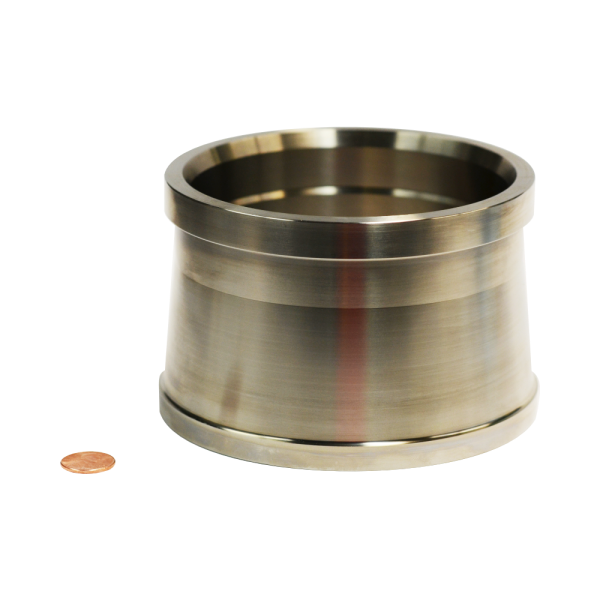

Titanium Forging Turned on Lathe